Conductors

Replacement of Bare Overhead Distribution Conductor with HTLS E-Beam Cured covered Conductor

In India, overhead power distribution lines using bare conductors are afflicted by issues like tree falls, bird-related disturbances, line flashovers, tornado & hurricanes and overloads. These issues not only disrupt power supply but also pose risks to wildlife, especially in forested areas, coastal areas…

Read the story →

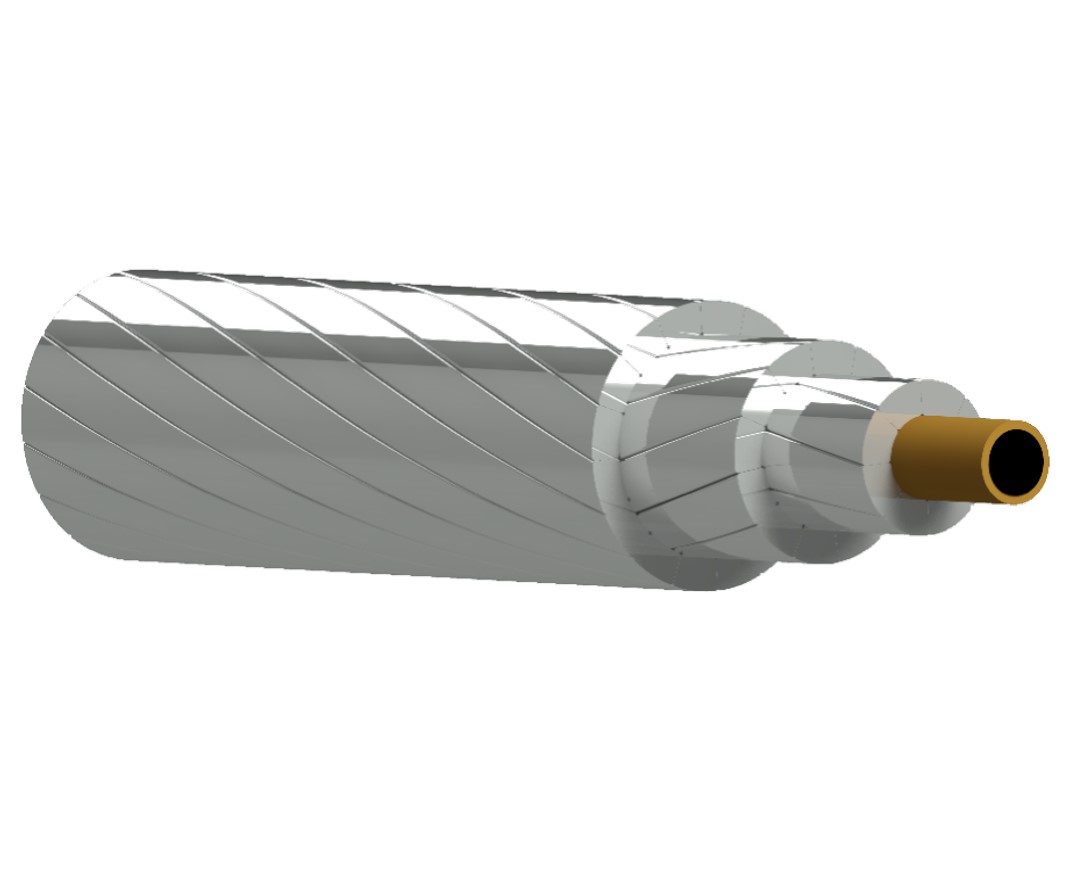

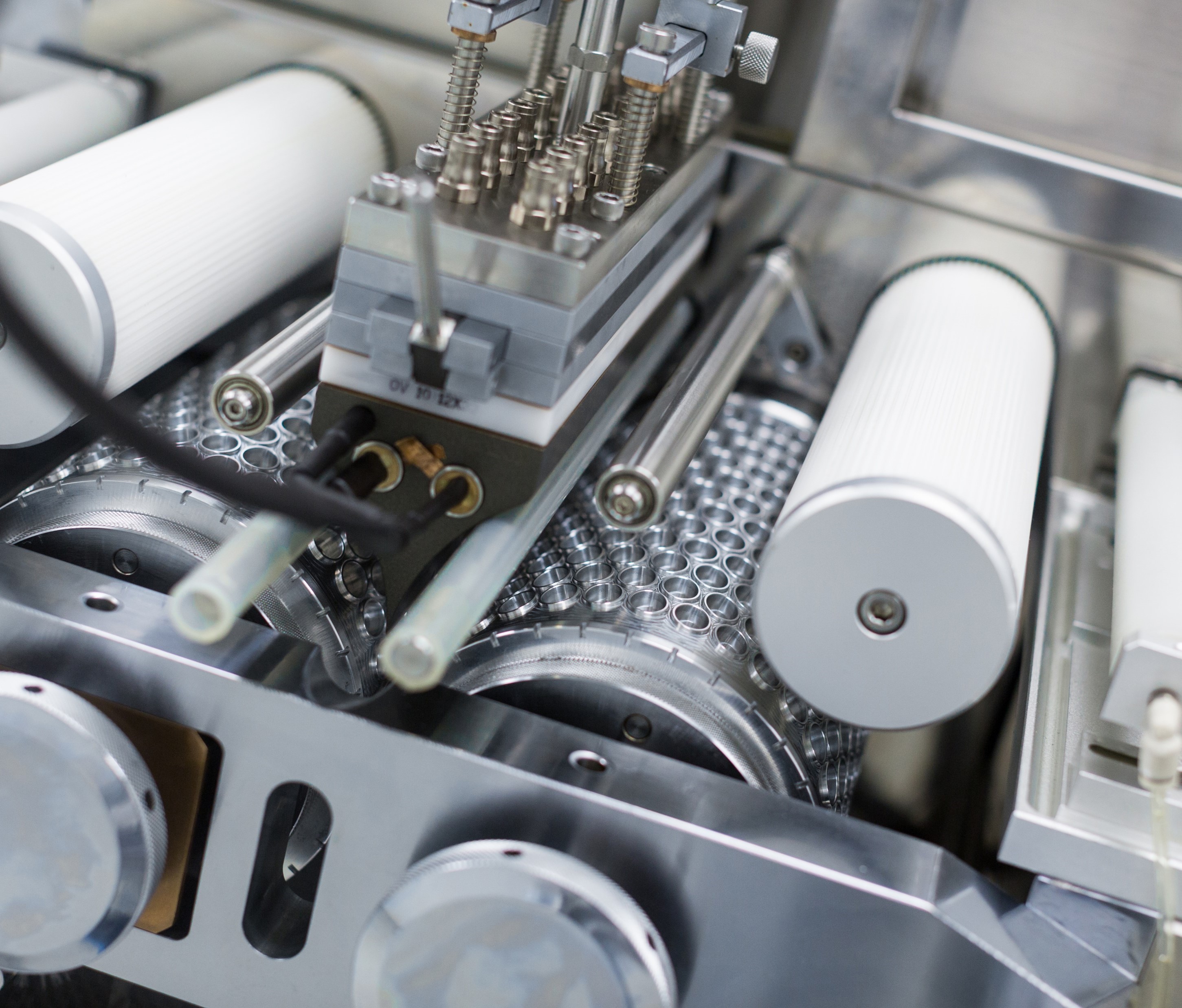

Solid Sector Shaped Aluminium Conductors – First in India

Manufacturing power cables with 3 or 4 cores had become a laborious and time-consuming process. The core of…

Read the story →

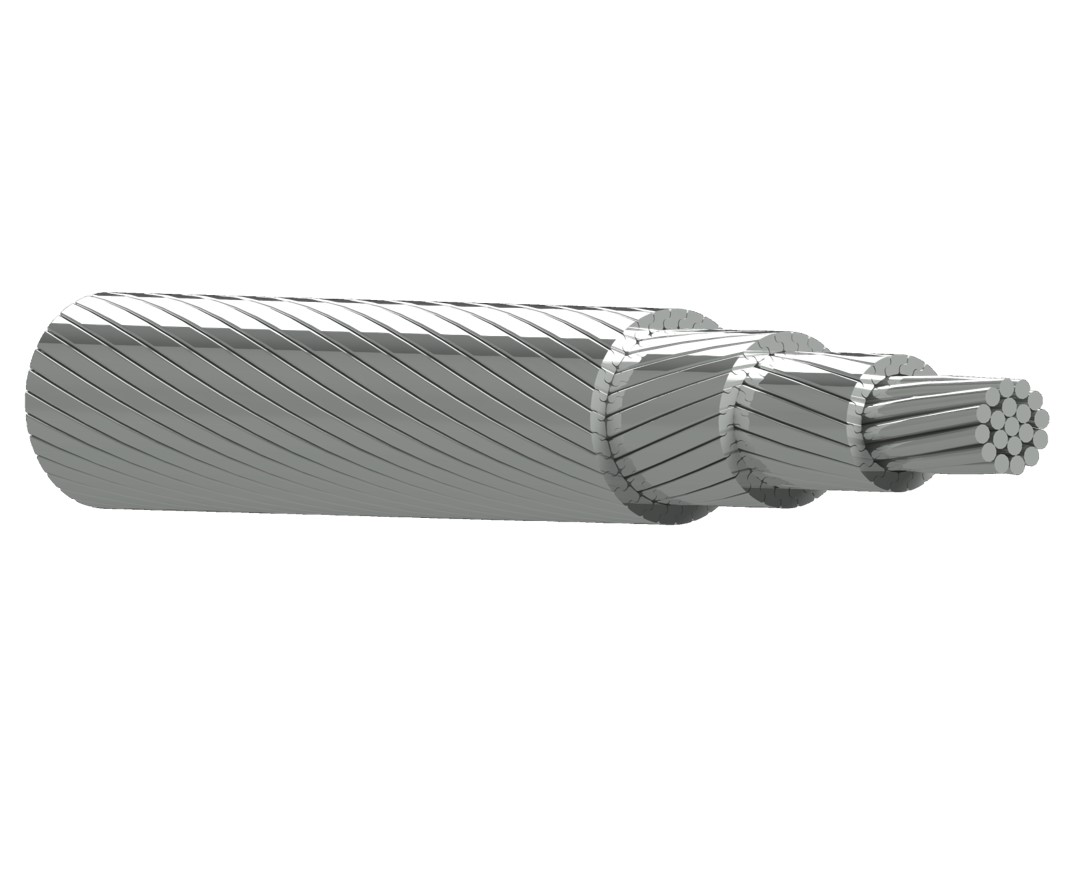

Innovative ACCC Conductor design & turnkey solutions

APAR Conductor Division had a challenge to design a custom conductor for a 220 KV transmission line in India…

Read the story →

Innovative Power-ZAD Conductors

The power lines are always in motion, vibrating, and dealing with constant stresses from varied weather…

Read the story →

APAR’s Solution to Testing Challenges

The lack of domestic testing facilities for copper and copper alloy products in India has posed significant…

Read the story →

Setting up facility to reduce import dependence

One of India’s key growth drivers, the transformer manufacturers were facing serious demand-supply gap for…

Read the story →

Helping Indian Railways achieve 100% electrification

Indian Railways has set for itself a mammoth task of completing 100% electrification of its tracks…

Read the story →

Copper-magnesium wire production for Indian Railways

Indian Railways has planned to increase the speed of its existing system to 200 km per hour and is also planning to set…

Read the story →

Developing full range of HTLS conductors since 2010

As power transmission utilities across India aimed to transmit twice the power in the same transmission corridor, at…

Read the story →

Enabling transmission towers carry 40-60% more power

In 2011-12, Gujarat Energy Transmission Corporation Limited (GETCO) was looking for the most economical…

Read the story →

1st Indian company to create aluminium alloy 6xxx wires

Till 2008, aluminium alloy 6xxx series wires for mechanical alloys were imported into India…

Read the story →Cable Solutions

Supporting make in India’s electric vehicles and EV chargers

Our latest additions to cable solutions are automotive wires and wiring harnesses. The launch of these cutting-edge, next-generation products positions us as the first Indian cable manufacturer to venture into the EV segment, supporting the “Make in India” initiative.

Read the story →

Launched special FRP OFC cables for critical infrastructure projects

APAR has crafted and launched special non-metallic 12F/48F/72F Triple Sheath FRP Armoured Fibre Optic Cables designed for critical infrastructure. These cables provide robust performance for demanding applications requiring durability, reliability, and secure signal transmission.

Read the story →

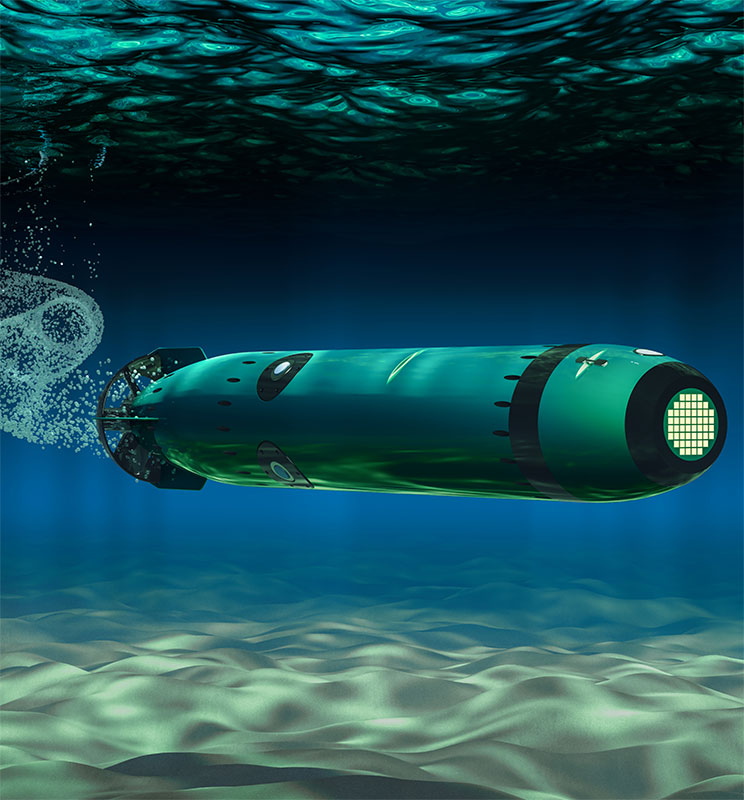

Create guidance optical fibre wires for torpedoes

Guidance optical fibre wires have always been imported into the country, leading to very high costs. APAR successfully developed these wires indigenously, supporting national defence initiatives with locally engineered, high-performance solutions.

Read the story →

Innovating Heat and melt-resistant high ampacity

The major source of fire in buildings is short circuits. Indian buildings typically have PVC insulated wires that may not withstand extreme heat. APAR innovated heat and melt-resistant wires with high ampacity to significantly improve electrical safety in multi-storey buildings and industrial spaces.

Read the story →

Innoated tether cables for airborne surveillance

For several years, the tether cables required by defence installation systems for airborne surveillance were imported. APAR innovated and produced these cables domestically, ensuring robust performance in demanding military and strategic surveillance applications.

Read the story →

1st Indian company to create aluminium alloy 6xxx wires

Till 2008, aluminium alloy 6xxx series wires for mechanical alloys were imported into India. APAR developed a full range of these alloys indigenously, reducing dependence on imports and strengthening India's manufacturing ecosystem.

Read the story →

Developing full range of HTLS conductors

As power transmission utilities across India aimed to transmit twice the power in the same transmission corridor, APAR developed a full range of HTLS conductors that significantly improve current-carrying capacity without modifying existing infrastructure.

Read the story →

Enabling transmission towers carry 40-60% more power

In 2011-12, Gujarat Energy Transmission Corporation Limited (GETCO) was looking for the most economical and feasible options to increase power capacity. APAR provided advanced solutions that enabled transmission towers to carry significantly higher loads.

Read the story →Speciality Oils

APAR develops a method to quantify copper corrosion

The transformer industry was seeing a high failure rate due to copper corrosion. The causes for failure were unknown. Even high and ultra-high voltage transformers were failing without explanation. APAR developed a scientific method to accurately quantify copper corrosion and mitigate risk.

Read the story →

Creating a range of oils with low-gassing tendencies

It is typically recommended that instrument transformers use gas absorbing oils with negative gassing. APAR developed a specialised range of low-gassing oils to enhance performance and safety of high voltage instrument transformers used across India’s power grids.

Read the story →

Special naphthenic high-grade inhibited oil for 800 kV HVDC transmission grids

800 kV HVDC systems were implemented in the country for the first time by a major national grid company. APAR created a high-grade inhibited naphthenic oil designed specifically for the unique demands of these extremely high-voltage systems.

Read the story →

Special naphthenic high-grade inhibited oil for 800 kV HVDC transmission grids

800 kV HVDC systems were implemented in the country for the first time by a major national grid company. APAR created a high-grade inhibited naphthenic oil designed specifically for the unique demands of these extremely high-voltage systems.

Read the story →Polymers

Zero PPM Award from Toyoda Gosei South India

Toyoda Gosei South India Private Limited practices the Just-In-Time (JIT) system to maintain low inventory and requires exact and timely delivery of raw materials. Imported raw materials had long lead times of over 90 days. APAR’s domestic solution drastically reduced lead time while ensuring Zero PPM quality, earning the prestigious award.

Read the story →

Recognised as the ‘most cost-effective vendor’

In one of their projects, Lumax Cornaglia Auto Technologies Pvt. Ltd. was using imported materials. APAR provided a superior domestic alternative that not only matched performance requirements but also dramatically improved cost efficiency, earning recognition as the most cost-effective vendor.

Read the story →

Creating anti-skid, matte finish car mats for the European market

One of APAR’s customers, a leading manufacturer and exporter of car foot mats in the European market, was seeking a specialised anti-skid, matte polymer compound. APAR developed a customised formulation that met strict European quality norms and enhanced the product’s export competitiveness.

Read the story →

Developing full range of HTLS conductors

As power transmission utilities across India aimed to transmit twice the power in the same transmission corridor, APAR developed a full range of HTLS conductors that improved thermal resistance, tensile strength, and overall performance without requiring new infrastructure.

Read the story →

Enabling transmission towers carry 40-60% more power

In 2011-12, Gujarat Energy Transmission Corporation Limited (GETCO) sought efficient ways to increase power capacity without costly tower replacements. APAR’s advanced conductor technologies enabled existing towers to carry significantly more power safely and cost-effectively.

Read the story →Lubricants

High-temperature chain lubricant POWEROIL® HTCO

In various industries such as food, automotive, textile, tiles and plywood, chain drives or conveyors play a crucial role in transmitting force and motion. Each chain joint in a bearing requires proper lubrication to ensure maximum service life, as the strength of a chain is determined by its weakest link.

Read the story →

Introducing water based rust preventive oil

Our product range has evolved to surpass the expectations of our customers. We created “POWEROIL RP Aqua 3050”, a water-based rust preventive solution that minimises environmental impact while providing powerful, reliable protection for metal components during processing and storage.

Read the story →

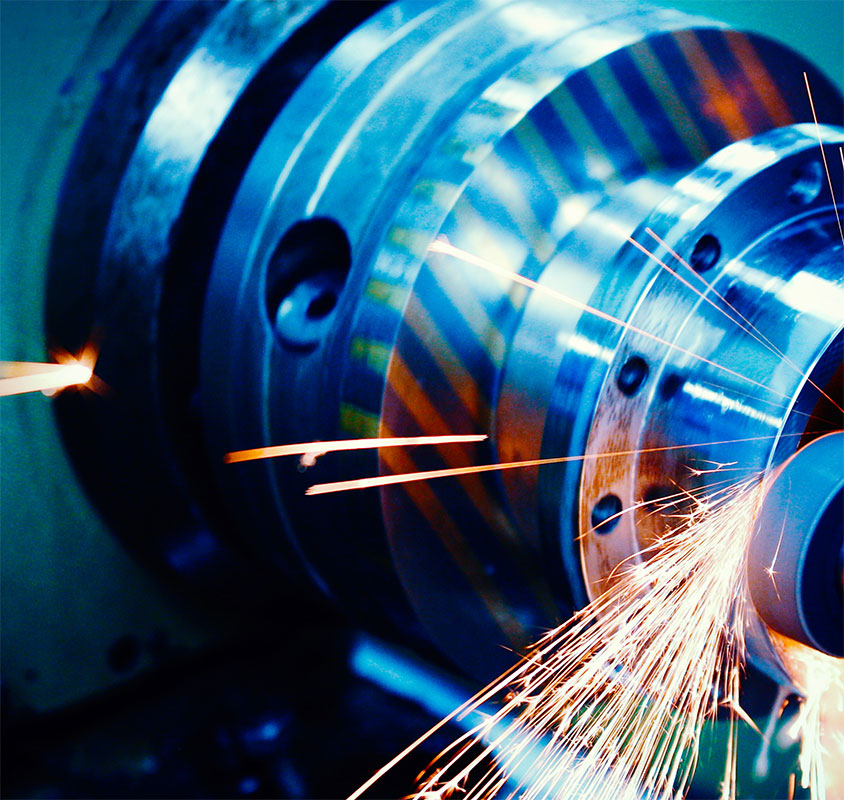

Creating a semi-synthetic metal working fluid

Our client, a connecting rod manufacturer, was having issues running their entire machining process. APAR developed a tailored semi-synthetic metal working fluid that improved cooling, lubrication, and tool life, resulting in superior machining performance and reduced downtime.

Read the story →

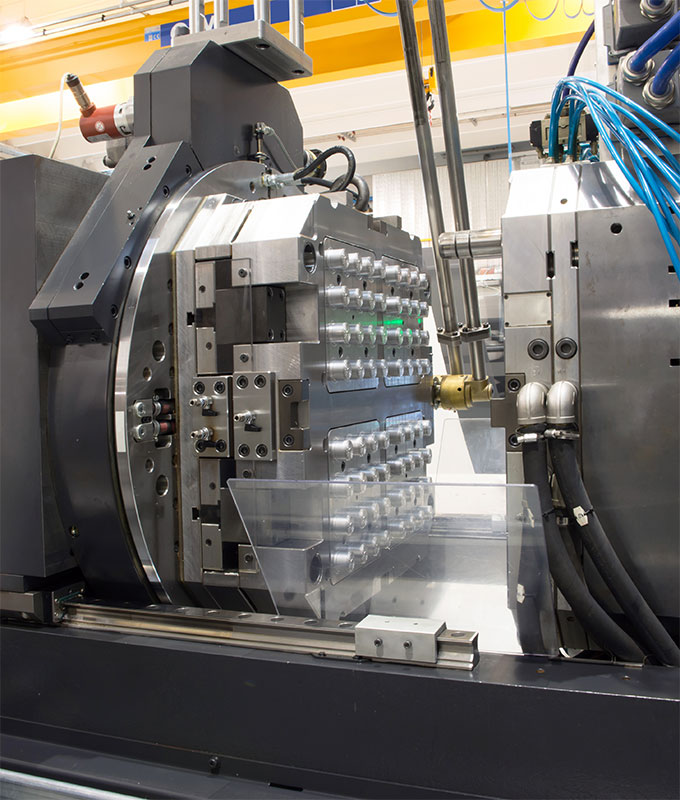

Innovating for the injection moulding industry

The injection moulding industry was dominated by international suppliers, and all OEMs based in India relied heavily on imports. APAR developed innovative lubricants that enhanced operational efficiency, reduced defects and improved cycle times for injection moulding applications.

Read the story →

Creating a non-foaming, semi synthetic MW oil

The biggest challenge for machining a forged steel component is dissipating heat quickly during heavy material removal. APAR developed a non-foaming semi-synthetic MW oil that significantly improved heat transfer, lubrication and tool performance under extreme machining conditions.

Read the story →Speciality Automotive

First Indian company to get AdBlue certification

Diesel engines exhaust two of the most harmful gases—nitrogen oxide and nitrogen dioxide—that contribute to smog, acid rain and other environmental issues. The emission of these gases can be curbed using a solution called AdBlue injected into the exhaust via the Selective Catalytic Reduction (SCR) system. APAR became the first Indian company to be certified for producing AdBlue.

Read the story →

Tension-free mornings for car and bike owners

One of the key issues faced by car and bike owners is that the vehicle refuses to start, especially in cold weather. APAR created advanced automotive lubricants formulated to ensure smooth engine starts, protection from wear, and a longer engine life—making morning troubles a thing of the past.

Read the story →

India’s first battery brand to offer online warranty registration

If a consumer fails to retain the physical warranty card, they lose all warranty claims for the battery. APAR revolutionised the automotive battery industry by offering online warranty registration—making battery ownership worry-free and customer-friendly for millions of users.

Read the story →

Innovating for the injection moulding industry

The injection moulding industry was dominated by international suppliers, and all OEMs based in India relied heavily on imports. APAR developed innovative lubricants that enhanced operational efficiency, reduced defects, and improved cycle times for injection moulding applications.

Read the story →

Creating a non-foaming, semi synthetic MW oil

The biggest challenge for machining a forged steel component is dissipating heat quickly during heavy material removal. APAR developed a non-foaming semi-synthetic MW oil that significantly improved heat transfer, lubrication, and tool performance under extreme machining conditions.

Read the story →