The vision that guides us

APAR’s journey to becoming the world’s largest manufacturer of conductors with loyal customers in 107 countries spans across six decades. As a leading global supplier, we offer a full range of both conventional and new-generation speciality conductors.

Quality, integrity and sustainability reflect in everything we do at APAR. To maintain total control over the entire process, from design to manufacturing to testing, we’ve set up world-class manufacturing and ILAC MRA accredited testing facilities.

World-class output at every stage

APAR’s modern plants at Silvassa and Odisha in India enable us to produce world-class quality in massive capacities. We maintain total in-house control over the design, manufacturing and testing process. This enables us to guarantee innovation and quality while maintaining cost competitiveness.

Our commitment to leading the innovation curve is why we’ve pioneered turnkey solutions for reconductoring with HTLS, live line installation with OPGW and environmentally-friendly packaging solutions. Six decades of experience and expertise is hard to replicate.

Our factory processes have been perfected over six decades

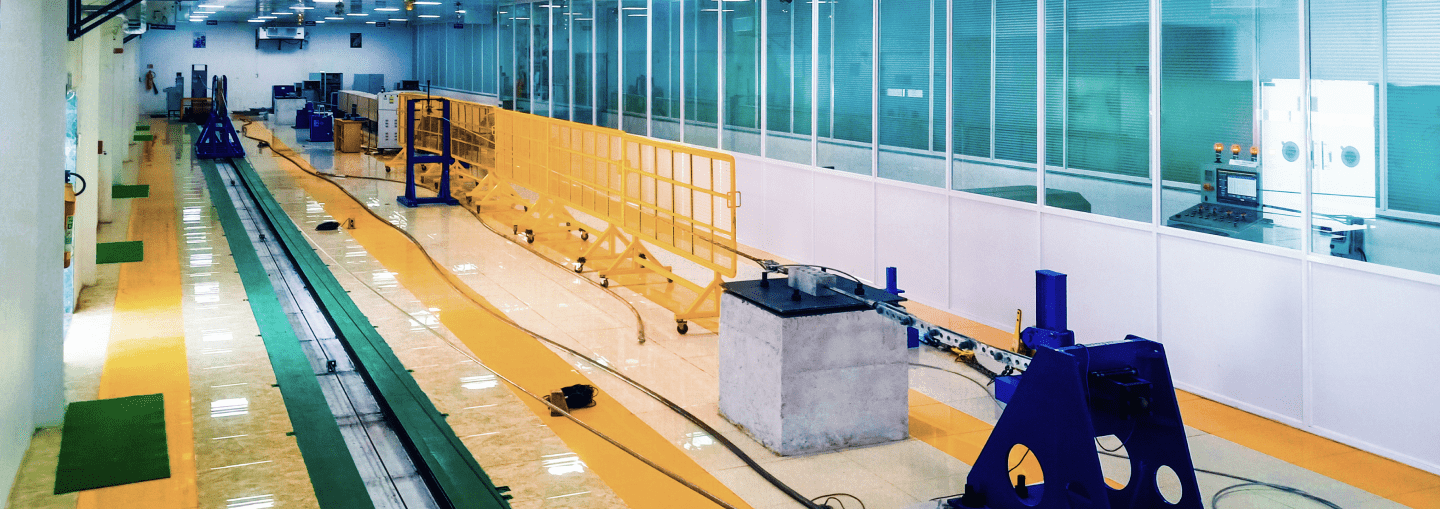

Modernisation and Digitalisation of Conductor Division Laboratory

The Conductor Division Laboratory has successfully implemented a thorough modernisation & digitalisation, using modern data acquisition system, and automation. This includes software & sensors for real-time data collection and reduction as well as real-time analysis, streamlining testing, reducing manual intervention, and ensuring accurate, efficient results. Employee training, quality assurance, data management, and remote monitoring further enhanced the laboratory's competitiveness and effectiveness in meeting global standards.

Rigorously tested

APAR’s testing laboratory specialises in physical, electrical, mechanical and chemical testing on overhead bare aluminium conductors, including new-generation conductors (INVAR/GAP/ACSS/ACCC ), OPGW cables, corrosion-protection greases for bare overhead conductors, their constituent components and several others.

Sustainably and safely packed

At APAR, conductors are shipped in sturdy, carefully-designed reels and drums that safeguard the conductor from damage in transit, storage, and installation. To prevent deforestation and create more eco-friendly packaging solutions, APAR has created recyclable steel and hybrid drums and woodless low-weight hybrid drums. These packaging innovations are recyclable, 40% lighter and more cost effective.

Our clients

We have worked with some of the most prestigious clients across industries