EPC Solutions

Specialized EPC Solutions

Medium Voltage Covered Conductor (MVCC) with enhanced temperature up to 105°C)

APAR HTCC, HRACC & HCCC (Covered Conductors)

are developed with the following special features:

- The conductor is designed for higher operating temperatures.

- The conductor strength member is a high-strength core.

- Functionally safe and reliable against accidental contact with other conductors, ground wires, trees, etc.

- Reduced or no risks of electrical shock and wildlife interference.

- Environmentally proven against corrosion or ingress of water.

- Increased power throughput and reduced losses.

- High reliability of operation, making it more efficient for distribution sectors compared to ordinary covered conductors.

- Reduced “Right of Way” by about 40% compared to a standard bare line.

- Lower operation and maintenance costs.

- Superior insulating material: UV-resistant with anti-tracking properties and the ability to sustain high temperatures up to 105°C, ensuring safe, long-term operation.

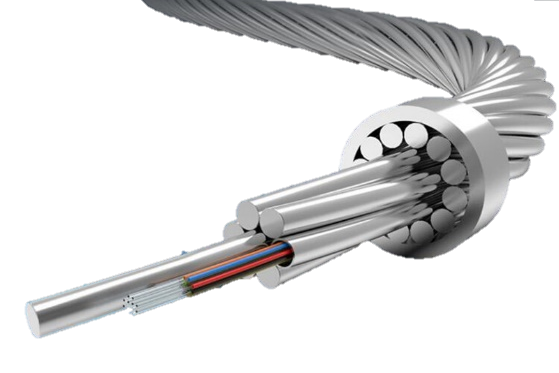

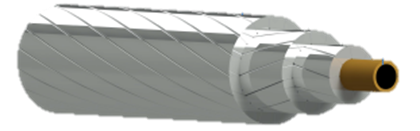

Optical Phase Conductor (OPPC)

- OPPC cable has the dual function (phase conductors cum data transmission and Sensing line data). The basic construction is similar to conventional phase conductor with optical units.

- OPPC is designed to maintain the mechanical and electrical characteristics of the phase wire it replaces. It replaces one or several wires of the conductor with stainless steel tube and strands the tube with ACS / Steel wires and Aluminium / Al. Alloy wires.

- There is no additional load on the original tower and no running defects like lightning break, short circuit current overheating.

Salient Features:

- Leverages existing power lines, eliminating the need for costly and disruptive ducting or underground cabling.

- High hanging point, reducing theft risk compared to low-hanging products.

- Provides an efficient solution for Fiber to the Home (FTTH) deployments, expanding broadband access without new infrastructure.

- Simplifies maintenance by using existing power infrastructure, reducing repair costs and downtime.

- Faster and cheaper to install compared to traditional fiber, lowering costs.

- Enables Digital Transformation with high-speed, low-latency connectivity for smart cities, 5G and IoT, driving digital services and data-driven utilities.

- Enables real-time grid monitoring for temperature, strain, and other conditions.

- Is compatible with Distributed Temperature Sensor (DTS) technology for continuous temperature measurement along the cable.

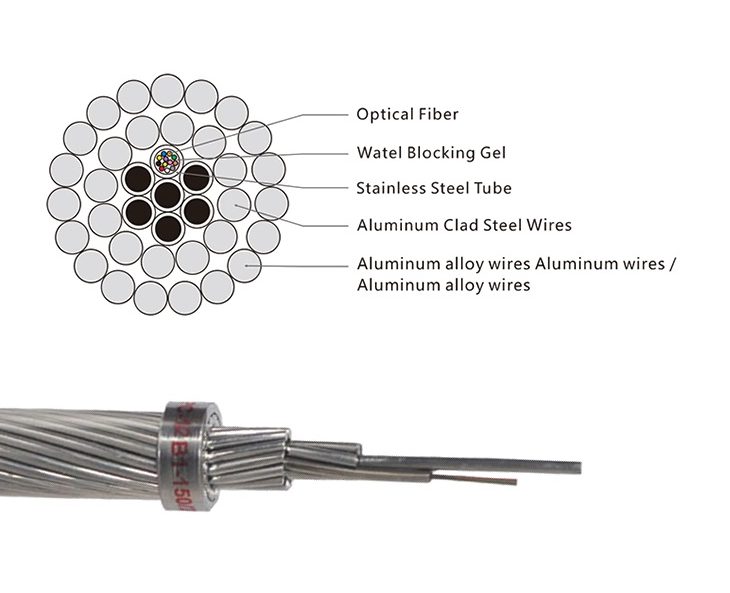

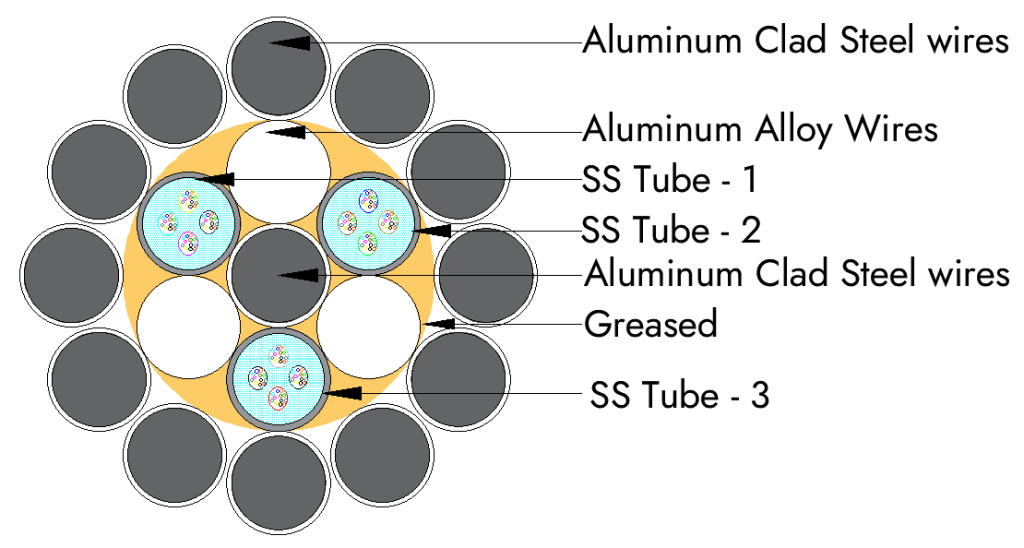

96F/144F Optical Ground Wire (OPGW)

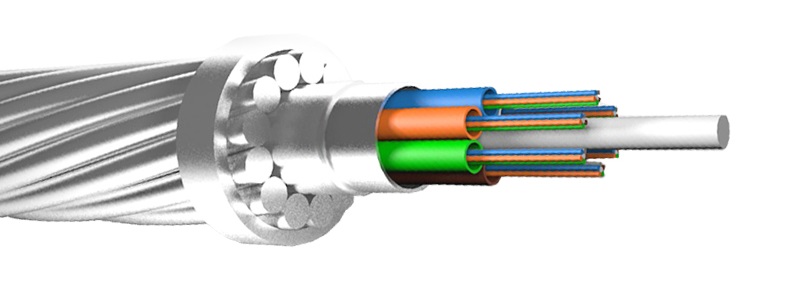

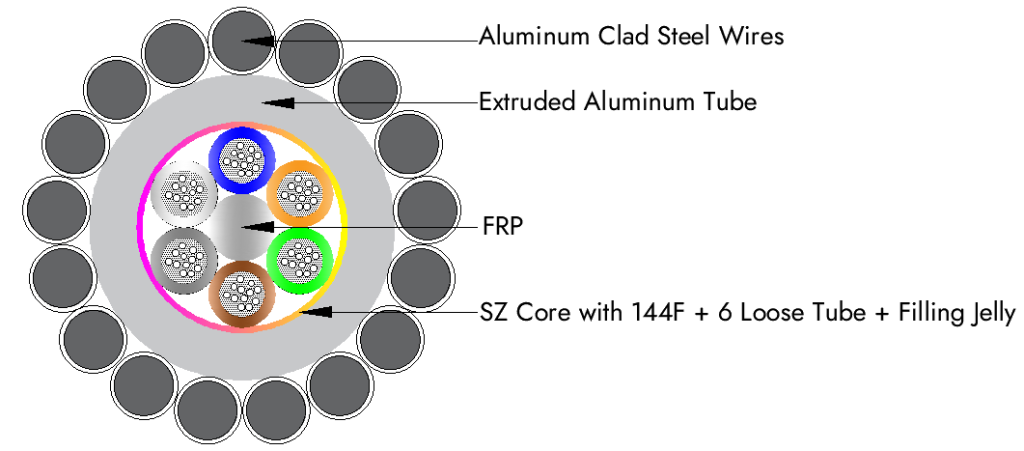

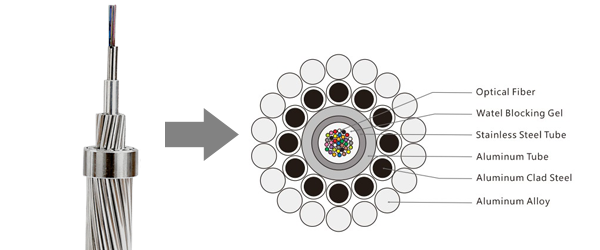

OPGW Cable with SUS Tube

OPGW Cable with AL Tube

Central Aluminium Tube Type

- Optical Ground Wire is a dual functioning cable. It is designed to replace traditional static / shield / earth wires on overhead transmission lines with the added benefit of containing optical fibers which can be used for telecommunications purposes

- 96/144F OPGW cable provides cost-effective solution to optimize the existing infrastructure over its operational lifespan. Provides quality assurance in maintaining network reliability, minimizing downtime and avoiding expensive repairs or replacements.

- Caters to anticipated future growth and bandwidth demands to prevent premature obsolescence.

OPGW Cable with SUS Tube

- The OPGW design consist of multiple stranded Stainless steel tube carrying optical fibers up to 144F.

- Laser-welded, hermetically sealed stainless steel tubes provide mechanical and thermal protection for fibers.

- This design has comparatively small diameter, low weight reduces retrofit impact.

OPGW Cable with AL Tube

- The OPGW design consist of Aluminum tube containing plastic loose tubes carrying optical fibers up to 144F.

- Thick-walled aluminum tube provides crush resistance and boosts fault current rating.

- The Aluminum tube offers high anti-corrosive properties.

Salient features:

- OPGW’s can carry up to 144 optical fibers, providing high capacity for data transmission.

- Cost-Effective Solution optimizes existing infrastructure.

- Reduced need for expensive repairs/replacement and extended lifespan.

- Higher Fiber count for increased bandwidth and ability to handle more data streams.

- Built-in redundancy for fault tolerance and resilient communication in comparison to conventional earth wires.

- Enables simultaneous transmission for various applications (DLR, DMS, Data centers, smart grid, etc.).

- Future-Proofing to meet growing data and bandwidth demands.

- Enhanced Monitoring with more fibers support additional sensors and real-time data collection

- Reduced risk of signal degradation and supports long-distance communication.

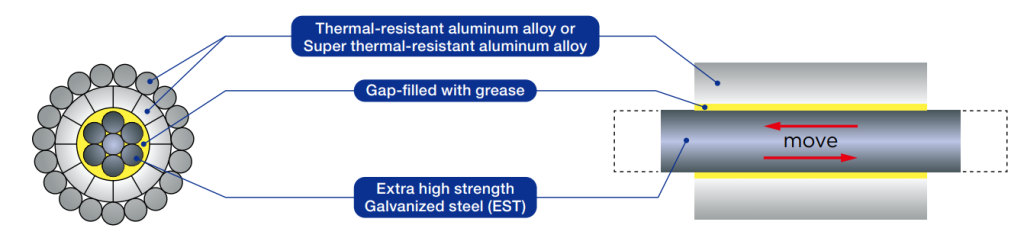

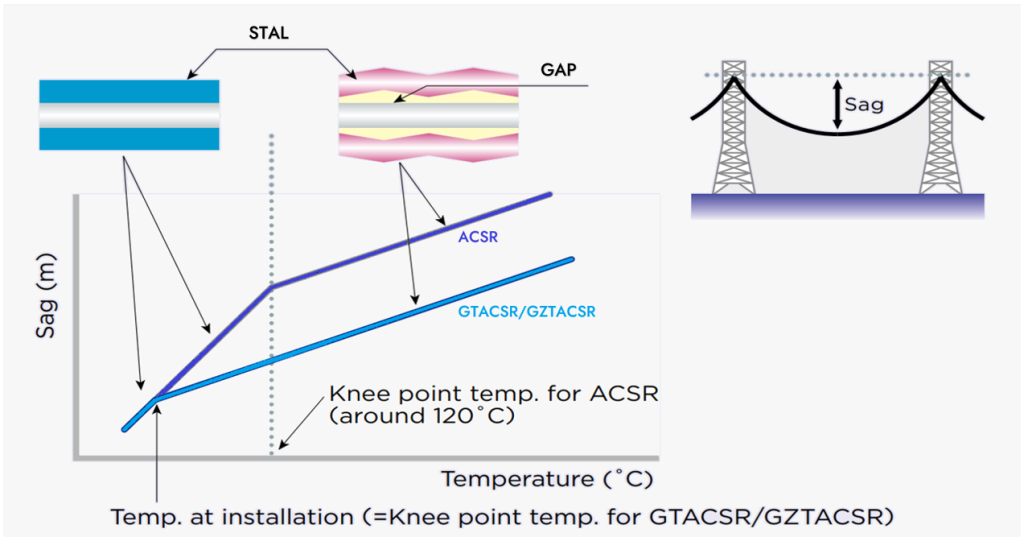

GAP Type Thermal-resistant Aluminum Conductor, Steel Reinforced (GZTACSR)

- Gap-type aluminum conductor steel reinforced (GZTACSR) uses heat-resistant aluminum over a steel core. A small annular Gap is maintained between a high-strength steel core and the first layer of aluminum alloy strands. The gap between the first layer trapezoidal shaped aluminum strands and the steel core is filled with high thermal resistant grease to avoid friction between steel and inner layer of aluminium.

- The thermal resistant grease gives it a better corrosion resistance and improves overall thermal performance.

Applications:

- No modification or reinforcement required for existing towers, Hence, ideal for reconductoring projects.

- Can be deployed in existing structures or can reduce strain on structures, increasing life expectancy of conductor.

- Has double the current-carrying capacity for the same size of conductor.

- At the time of sagging, tension is applied to the steel core by a special stringing method. As a result, the thermal expansion is that of steel core, lower thermal expansion maintains small sag at high temperature.

GZTACSR advantages over ACSR Conductor:

- Maintains the mechanical strength of the conductor at higher operating temperature up to 150°C & 210°C resp.

- Low Sag at high temperatures

- Low thermal knee point

- Tension is applied independently on the core to have the knee-point at the installation temperature

- In case of reconductoring of transmission line, special type of compression dead end assembly is used during installation of GAP type conductor, and the other accessories remain the same

- A very cost-effective solution for enhancing the power transfer capacity of existing lines

Co-efficient of thermal expansion (/°C)

Aluminum Conductor Composite Core (ACCC) Ultra Low Sag Conductors

ACCC conductors are HTLS Conductors with excellent electrical characteristics, excellent sag tension characteristics and superior corrosion resistance. Covered ranges from 14.35mm (min.) OD to 44.75mm (max) OD and suitable for 132kV, 200kV, 400kV. It provides a resilient solution for overhead transmission systems and fastest and cost-effective way to increase line capacity.

Salient features:

- Core is made of composite material (glass fiber & carbon fiber matrix) – High Strength & Ultra High Strength

- Offers lowest sag among the HTLS category due to lowest coefficient of thermal expansion and higher strength to weight ratio.

- Can operate up to 180°C & maximum emergency temperature up to 200°C

- Composite core as strength member permits higher tensioning during installation

- Provides high ampacity at low RAC losses

- Improves reliability & resilience

- Powers sustainable future and helps achieve de-carbonization goals with significantly lower overall carbon footprint and Lifecycle Assessment (LCA) benefits

EPC Solutions - Cables

Airport Lighting Cables

Airport Lighting Cables are specialized cables used for powering lighting systems at airports, including runway edge lights, approach lights, and taxiway lights. These cables ensure safe and reliable operation, even under extreme weather conditions.

Features & Specifications:

- High Voltage Insulation: Typically rated for 5kV or higher to withstand transient voltage fluctuations.

- Weather Resistance: Designed to endure harsh environmental conditions, including UV exposure, extreme temperatures, and moisture.

- Flame Retardant & Low Smoke: Manufactured with low-smoke, halogen-free materials to ensure safety during fire hazards.

- Mechanical Durability: Resistant to mechanical stress and abrasion due to heavy-duty jacketing.

- Compliance: Meets global aviation standards such as FAA L-824, ICAO, and IS specifications.

Applications:

- Airfield lighting systems (runways, taxiways, and approach lights).

- Underground installations for safe and efficient power transmission.

- Navigation lighting systems for aviation safety.

Screened & Instrumentation Cables

Screened and Instrumentation Cables are used in industrial control systems, automation, and process industries to transmit low-voltage signals with minimal interference.

Features & Specifications:

- Screening & Shielding: Available in various shielding configurations (individual, collective, and overall screening) to protect against electromagnetic interference (EMI) and radio frequency interference (RFI).

- High-Quality Conductors: Made with high-grade copper or aluminum for excellent signal integrity.

- Oil, Chemical & Moisture Resistant: Ensures longevity in industrial environments.

- Flame Retardant & Low Smoke: Ensures safety in hazardous areas.

- Voltage Rating: Typically rated for 300V to 1100V, depending on application.

Applications:

- Industrial automation and process control.

- SCADA (Supervisory Control and Data Acquisition) systems.

- Power plants, refineries, and petrochemical industries.

- Data transmission in electrical substations.

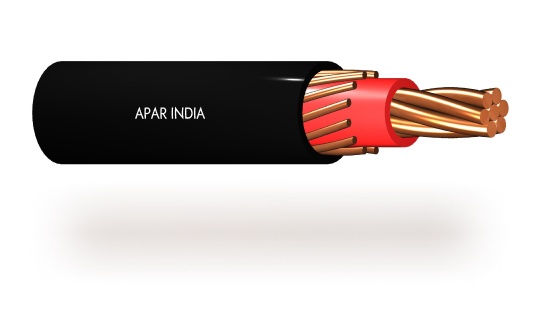

Concentric Core (Anti-Theft) Cable

Concentric Core (Anti-Theft) Cables are designed to prevent electricity theft, ensuring reliable and secure power distribution. They are commonly used in urban and rural electrification projects.

Features & Specifications:

- Anti-Theft Design: The concentric conductor arrangement makes unauthorized tapping difficult.

- High Mechanical Strength: Resistant to tampering, cutting, and unauthorized connections.

- Corrosion Resistant: Protected against environmental factors to ensure a long lifespan.

- Available in Different Configurations: Single-core and multi-core variations based on voltage requirements.

- Standards Compliance: Conforms to IS, IEC, and utility specifications for anti-theft applications.

Applications:

- Power distribution networks.

- Rural and urban electrification projects.

- Smart grid and energy metering applications.

Hybrid Mining Cable

Hybrid Mining Cables are designed for the harsh conditions of mining and tunneling operations, integrating multiple functions such as power, control, and data transmission into a single cable.

Features & Specifications:

- Multi-Purpose Construction: Combines power, data, and signal cables in one for enhanced efficiency.

- Extreme Durability: Resistant to abrasion, impact, and mechanical stress in rugged environments.

- High Flexibility: Designed for easy handling and movement in dynamic mining applications.

- Chemical & Oil Resistance: Withstands exposure to oil, chemicals, and moisture in underground mines.

- Fire Retardant & Halogen-Free: Ensures safety in confined mining areas.

Applications:

- Underground and open-pit mining operations.

- Heavy-duty equipment and machinery in mines.

- Tunneling and excavation projects.

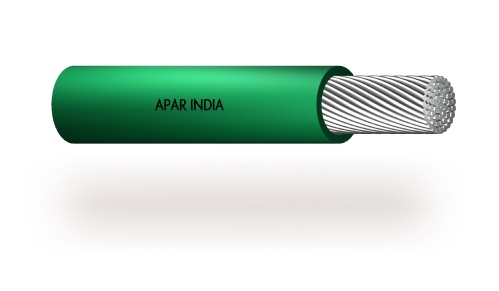

Aluminium Flexible E-Beam Cable

Aluminium Flexible E-Beam Cables are high-performance power cables that undergo electron beam (E-Beam) cross-linking to enhance their mechanical and thermal properties.

Features & Specifications:

- High Temperature Resistance: Can withstand extreme operating temperatures without degradation.

- Superior Flexibility: Offers ease of installation in applications requiring frequent bending.

- E-Beam Cross-Linked Insulation: Enhances thermal stability, mechanical strength, and longevity.

- Aluminium Core: Provides a cost-effective alternative to copper while maintaining conductivity.

- UV, Flame & Chemical Resistance: Ideal for outdoor and industrial applications.

Applications:

- Power distribution in industrial and commercial sectors.

- Renewable energy projects (solar and wind farms).

- High-temperature environments like steel plants and refineries.