Ribbon cables duct, armoured & aerial

Ribbon optical cables are used for duct, direct buried, and aerial installations. These cables have a specific design of water block yarn that helps eliminate the steps associated with standard gel-filled cables.

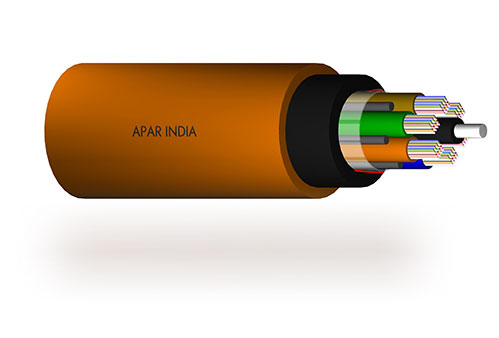

This is a stranded loose tube cable with optical fibres placed inside robust buffer tubes stranded around a fibre-reinforced plastic (FRP) central strength member.

In addition to optical fibres, the buffer tubes contain water-blocking gel and the cable core is surrounded with a water-swellable tape to prevent water ingress in the interstices of the cable core. Glass roving yarns are distributed over the inner sheath, and a thermoplastic jacket provides the cable with both mechanical and environmental protection.

| Application | Ribbon optical cables are intended for duct, direct-buried, and lashed aerial installations. These cables are used for fibre networks where a high fibre count is required. Ribbon fibre optic cables can be used in indoor FTTH networks and indoor/outdoor point-to-point applications. |

|---|---|

| Characteristics | These cables are lighter compared to the old gel-filled cables. This allows for easier cable handling, easy mid-span entry, and superior fibre access. |

| Applicable standards | IEC 60793, IEC 60794, Telcordia GR -20, TIA/EIA 598 |

| Product range | From 4F fibre up to 1000 single mode fibres in full compliance with ITU-T-G.652.D in 4/6/8/12 fibre ribbon (also available with G655 / G656 / G657 SM Fibre and OM1 / OM2 / OM3 & OM4 MM Fibre). These cables can be provided with unarmoured ducts for underground applications, ADSS for aerial use and armoured cables for direct buried applications. |

| Advantages | These cables are more installer-friendly, and lighter in weight than conventional gel-filled cables, and hence allow for easier handling, mid-span entry, and provide superior fibre accessibility. The first advantage of a ribbon fibre jumper is the ability to save time and reduce installation cost. Since the cables are pre-banded (usually made up of 12 sets of separate fibres), installers and technicians can perform simpler, faster mass fusion stitching so that all fibres in the ribbon matrix can be stitched together at the same time. This means less installation time, lower installation labour costs, and faster recovery during downtime.The second benefit of the ribbon fibre cable is the increased fibre density of the cable. Fibre density is an important benefit as it increases the fibre count at the data centre. |

Published On: January 20, 2021