Products of the Future

Cables

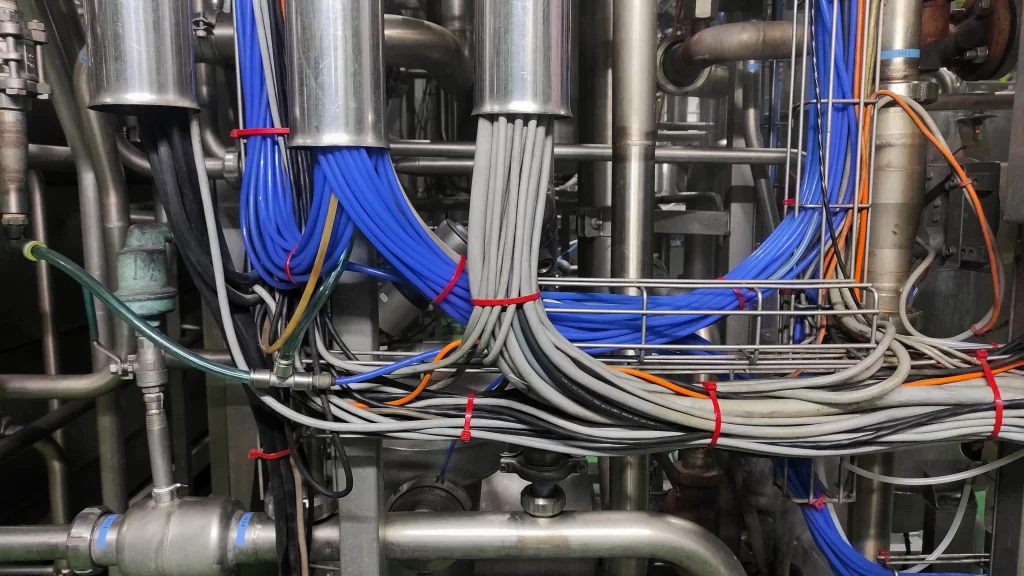

Pressure Tight (PT-45) Cable

Description:

APAR Pressure Tight (PT-45) cable is a specialized high-performance cable designed for industrial and military-grade applications. It is built to withstand extreme environmental conditions while providing excellent electrical performance.

Features:

- High-temperature resistance

- Rugged and durable construction

- Enhanced shielding for minimal signal interference

- Water-resistant and corrosion-proof

- High mechanical strength

Applications:

- Military and defense systems

- Aerospace applications

- Industrial automation

- High-performance power and data transmission

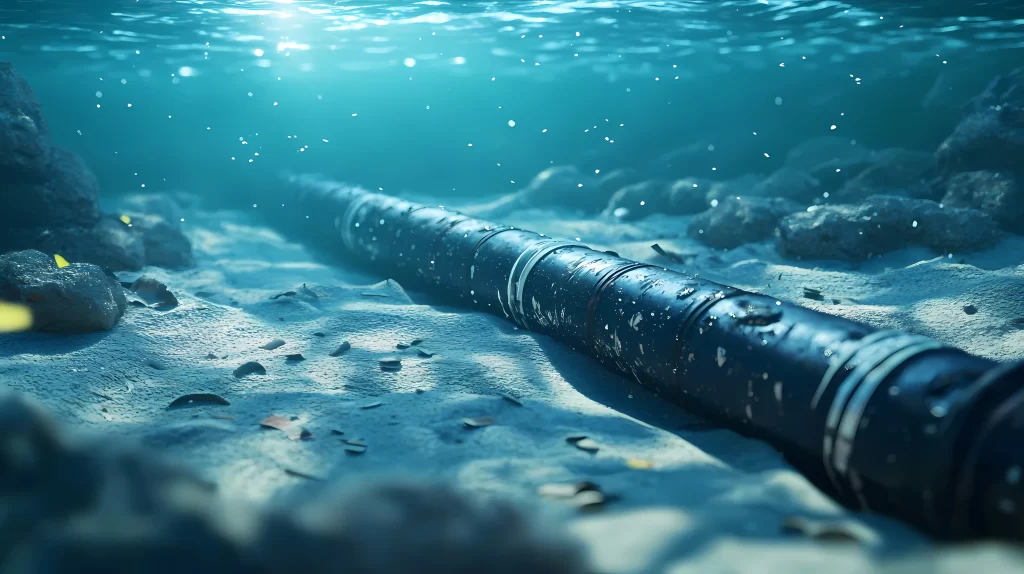

Submarine Underwater Cable

Description:

APAR Submarine cables are specialized cables designed for underwater communication, power transmission, and other applications. These cables are built with high durability and waterproofing capabilities to withstand harsh marine environments.

Features:

- High-strength armoring for underwater durability

- Corrosion-resistant materials

- Waterproof and pressure-resistant insulation

- Excellent electrical and signal transmission properties

- Designed to withstand deep-sea conditions

Applications:

- Offshore oil and gas platforms

- Underwater data transmission

- Power distribution between islands and coastal areas

- Naval and defense applications

- Oceanographic research

EV Charging Cable

Description:

APAR EV (Electric Vehicle) charging cables are used to connect electric vehicles to charging stations, ensuring efficient and safe power transfer. They comply with international safety and environmental standards.

APAR EV (Electric Vehicle) charging cables are used to connect electric vehicles to charging stations, ensuring efficient and safe power transfer. They comply with international safety and environmental standards.

Features:

- High-flexibility insulation for easy handling

- UV, oil, and abrasion resistance

- Flame-retardant and halogen-free materials

- High voltage and current carrying capacity

- Weather-resistant for outdoor use

Applications:

- Electric vehicle charging stations

- Home and public EV charging setups

- Fast-charging and supercharging stations

- Battery energy storage systems

Heavy Tow Cable

Description:

APAR Heavy tow cables are used in towing applications where strength, flexibility, and durability are crucial. These cables are designed to handle high loads and resist harsh environmental conditions.

APAR Heavy tow cables are used in towing applications where strength, flexibility, and durability are crucial. These cables are designed to handle high loads and resist harsh environmental conditions.

Features:

- High-tensile strength for heavy-duty applications

- Reinforced insulation for impact and abrasion resistance

- Superior flexibility for easy deployment

- Corrosion and water-resistant materials

- Customizable lengths and load capacities

Applications:

- Maritime towing operations

- Defense and naval applications

- Underwater vehicle operations

- Offshore and deep-sea exploration

Aluminum Flexiable E-Beam Cable

Description:

APAR Aluminum Flexible E-Beam Cables are advanced cables designed with electron beam (E-Beam) cross-linked insulation, providing enhanced electrical and mechanical properties. These cables are lightweight and ideal for high-performance applications.

Features:

- Low Smoke

- Low Halogen

- Heat Resistant @ 105 Deg. C

- Flame Retardant

- Anti – Termite

- Short Circuit Resistant

- Very Low Leakage

- Anti Oxidation Properties of Conductor

Special Features:

For single core wires

- 50% higher current carrying capacity than conventional Copper wires

For multi core cables

- 35% higher current carrying capacity than conventional Copper cables

*Cost saving of 25% as compared to Copper Flexible Cables

Applications:

- Aerospace and automotive industries

- Industrial power distribution

- Renewable energy applications

- Railways and metro systems

Conductors :

Coated Conductors

Features

- Reduces Overhead Conductor Temperature

- Increases Conductor Ampacity

- Improves efficiency by reducing energy losses, contributing to lower carbon emissions.

- Ensures stable power flow across all levels of solar radiation.

- Works by simultaneously reflecting solar radiation (80% solar reflectivity) and increasing heat dissipation (>0.90 emissivity).

- Repels Water, Preventing Moisture Damage

- Long-Lasting Protection Against Corrosion

- Durable against UV radiation, weathering and IR reflection.

High Conductivity Alloy Conductor – AL59

- AL59 conductors are made out of Al-Mg-Si low resistance high conductivity alloy with excellent electrical characteristics, excellent sag-tension characteristics and superior corrosion resistance to that of ACSR (Aluminium Conductor Steel-Reinforced). As compared to ACSR they have lighter weight, comparable strength and current carrying capacity

- The metallurgy and manufacturing of AL59 requires energy intensive processes for precipitation of SiMg2 phase. This involved multiple heat treatment processes to achieve consistency in parameters and manufacture first time right material

- With the consistent R&D efforts, thorough analysis and setting up the stringent process norms followed by several trials on various wire sizes, APAR team succeeded in achieving the desired wire parameters as per the technical specification by redefining the recipe which did not require the drawn wire to be heat treated thereby providing the following benefits:Improving the productivity Saving of electricity 13.75 units/ MT Material saving.

- These conductors offer better Conductivity, lower operating costs (due to lower ohmic losses) and can be recycled easily

- The conductors are available with Non-Specular (Dull) Surface Finish and Color Coated as per customized requirements

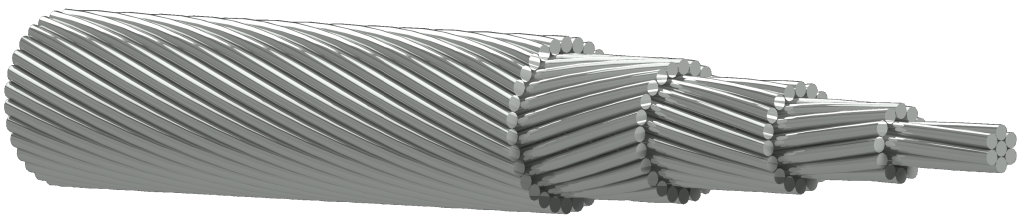

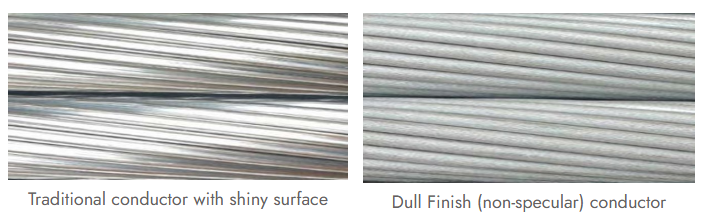

Aluminium Conductor Steel Reinforced (ACSR/TW) – Dull Finish

- ACSR/ TW are concentrically stranded conductors with one or more layers of hard drawn Aluminium wires on Aluminium Clad steel wire core.

- While the mechanical properties are similar to ACSR, these conductors but offers improved ampacity, better sag and resistance to corrosion because of the presence of Aluminium clad steel wires in the core

- We produce dull finish conductor to reduce the reflection of conductor surface due to aluminium luster, which offers following benefits:

- The surface emissivity increases from 0.23 to approx. 0.42.

- Improvement in current carrying capacity by 5%.

- Suitable for V, HV and EHV overhead, long distance transmission and distribution lines.

- Can be installed within the vicinity of airport as dull finish conductors eliminates the light scattering from conductors surface.

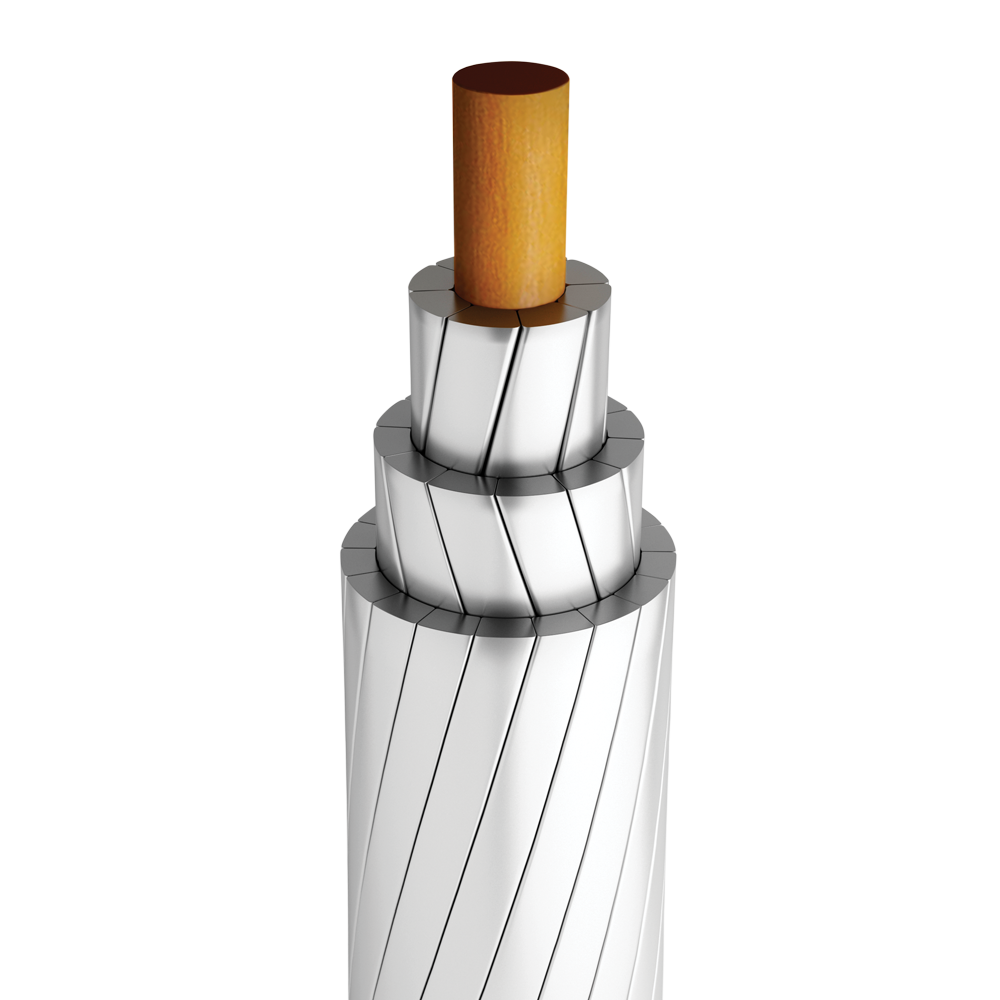

Aluminium Conductor Composite Core (ACCC) Conductors

- These are “High-temperature low-sag” (HTLS) Conductors with excellent electrical characteristics, excellent sag-tension characteristics and superior corrosion resistance to that of ACSR.

- As compared to ACSR they have lighter weight, comparable strength and current carrying capacity, lower electrical losses and superior corrosion resistance have given this conductor wide acceptance as a transmission conductor

- ACCC conductors are classified as low-carbon products because they offer significant advantages in material efficiency, reduced energy consumption during manufacturing, improved transmission efficiency, extended service life, and favorable results in lifecycle assessments

- ACCC conductors offer higher ampacity and resilience to environmental factors like ice and wind, resulting in lower power outages and a more reliable electricity supply for communities and industries

- The higher strength-to-weight ratio of these conductors reduces sagging and risks of line breaks, enhancing safety and reducing downtime for maintenance

- These factors collectively contribute to lower greenhouse gas emissions and environmental impact compared to traditional conductor designs, making ACCC a preferred choice for sustainable infrastructure projects

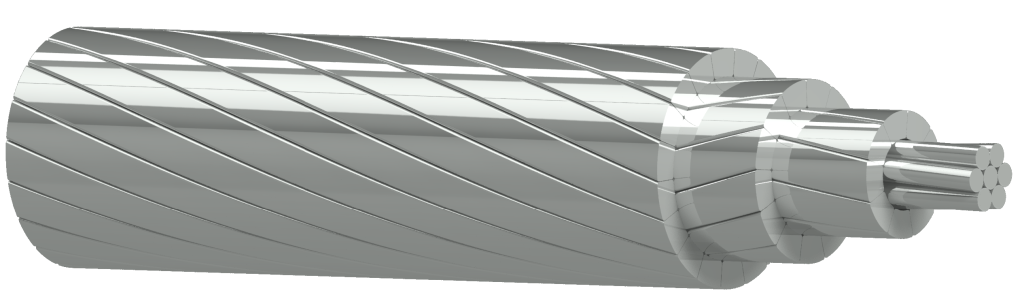

All Aluminium Alloy Conductors (AAAC) – Extra High Conductivity

These are made out of high strength Aluminium Magnesium-Silicon alloy. As compared to conventional ACSR, AAAC conductors are of lighter weight, comparable strength & current carrying capacity, lower electrical losses, generate less heat, and lower green house gas (GHG) emissions.

The conductors can be recycled easily; material efficiency due to high conductivity allows smaller conductors to carry more current and provide superior corrosion resistance.

- High Strength to Weight Ratio The use of Aluminium-Magnesium-Silicon alloy provides enhanced strength without significantly increasing weight, allowing for longer spans between support structures.

- Improved Sag Characteristics The alloy properties results in reduced sag under electrical load, maintaining clearance requirements and improving line performance.

- Corrosion Resistance AAAC exhibits better corrosion resistance compared to other conductors like ACSR, making it suitable for harsh environmental conditions.

- Enhanced Electrical Properties The extra high conductivity (EHC) alloy used reduces transmission losses, contributing to more efficient power delivery.

These conductors are available with Non-Specular (Dull) Surface Finish and Color Coated as per customized requirements.

Transforming Industries Toward Sustainability: APAR's Innovations

WE ARE THE WORLD’S 3RD LARGEST PRODUCER OF TRANSFORMER OIL.

For over five decades, POWEROIL has been leading the innovation curve in the transformer oils segment and meeting various international performance standards. The entire range of transformer oils has been developed through our in-house R&D efforts. We have developed the right capabilities and expertise for product innovation, quality, and timely service to our customers.POWEROIL TO-NE: THE SUSTAINABLE CHOICE FOR TRANSFORMERS

POWEROIL TO-NE Natural ester dielectric fluid, the next generation of transformer protection.- Sustainable and readily biodegradable

- Formulated from selective renewable natural ester feedstock

- Excellent fire safety requirements – K2 fluid with fire point > 300˚C

- Higher water saturation solubility

- Complying with IEC 62770/IS 16659 standards

Applications: Floating solar transformers, transformers in offshore windmills, ships, islands, marine systems, and mining sites.

POWEROIL TO-SE: WHERE EFFICIENCY DRIVES EXCELLENCE

POWEROIL TO-SE Synthetic ester dielectric fluid, engineered for performance and reliability.- Excellent fire safety requirements: K3 fluid with fire point > 300° C

- Excellent oxidation stability exceeds: IEC 61099 & IS 16081 standards

- Superior moisture tolerance: absorbs large amount with no impact on breakdown voltage

- Extends cellulose life by absorbing moisture from cellulose into fluid

- Fully biodegradable: no toxicity

- Ideal for cold weather conditions: very low pour point

- Outstanding dielectric properties

- Retro-filling of transformers: increases the life of solid insulation

Applications: Power and distribution transformers, free breathing and sealed transformers, floating solar transformers, locomotive transformers, transformers in offshore wind mills, ships, islands, marine systems, and mining sites.

POWEROIL PIN ULTRA HIGH VOLTAGE DIRECT CURRENT

Driving India’s ultra-high voltage future as the sole Indian supplier of 800kV UHVDC transformer oil, a trusted provider of 1,30,000 KL of inhibited high-grade naphthenic oil, with a prominent presence in 765kV AC.- Supplied to HITACHI ABB India in 2022

- Manufactured transformers for POWERGRID’s 6000 MW, 800 kV UHVDC – Raigarh – Pugalur in 2022

- Completed 400 kV HVDC Voltage Source Converter (VSC) based link – Aarey – Kudus in 2024