The vision that guides us

APAR’s journey to becoming the world’s largest manufacturer of conductors with loyal customers in 107 countries spans across six decades. As a leading global supplier, we offer a full range of both conventional and new-generation speciality conductors.

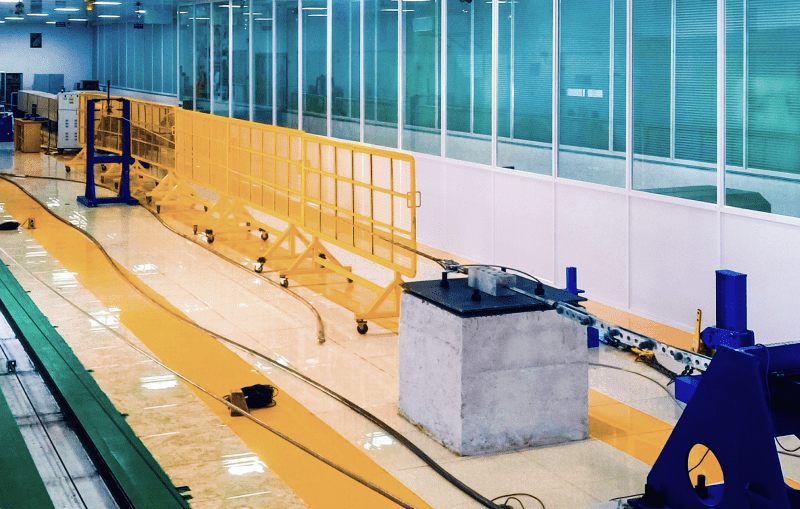

Quality, integrity and sustainability reflect in everything we do at APAR. To maintain total control over the entire process, from design to manufacturing to testing, we’ve set up world-class manufacturing and ILAC MRA accredited testing facilities.