The APAR difference

- APARPRENE® Modified-TPU has modified blends of TPU for typical applications of tubing, roofing sheet, lining in air ducts, cables, compensators to dampen vibration in pipelines and different types gaskets for industrial applications.

- It has excellent flexibility, resistance to cracking, good memory in a wide temperature range. It is not easy to twist, and it is easy to return to its original shape.

- It has characteristics of weldability, oil resistance, chemical resistance & grease resistance.

- Modified-TPU makes latest generation of high-end pipes, which can be made into oil pipes, water pipes, compressed air pipes, pneumatic components, pneumatic pipes, etc.

Applications of Modified-TPU Compounds in Industrial

APARPRENE® Modified-TPU has modified blends of TPU with excellent flexibility, resistance to cracking, good memory in a wide temperature range. It has fine characteristics of weldability, oil resistance, chemical resistance, & grease resistance, etc.

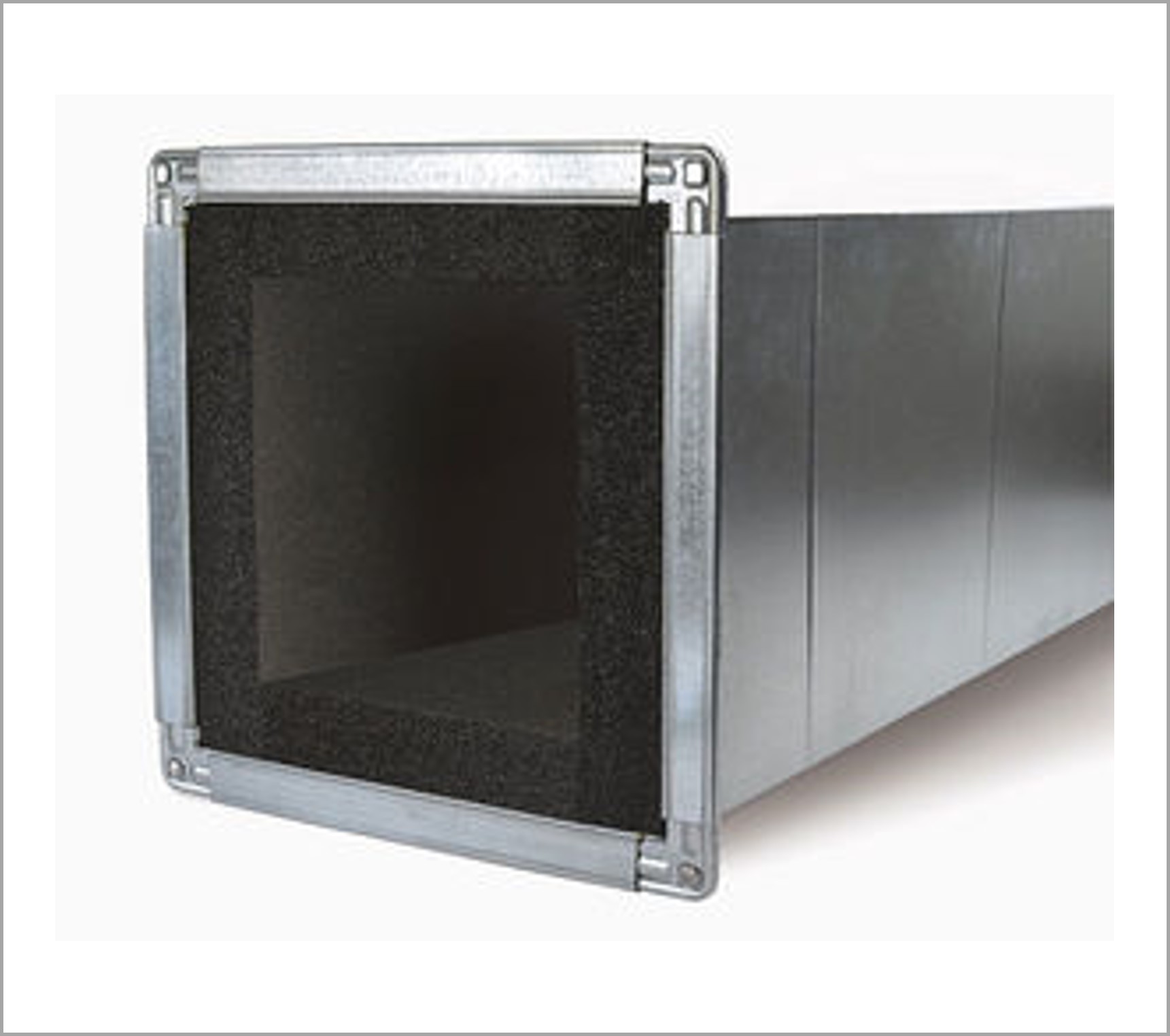

Applications of Modified-TPU Compounds in Building, Construction & Hand Tools

The traditional materials used in building & construction industry such as pipes, plastics, and other components have a long life but if TPU is used their life-span can be even further extended. Its excellent temperature, resistance to oil, chemicals, ageing and abrasion, lack of corrosive properties, lightweight, non-toxic, environmentally friendly properties make the APARPRENE® Modified-TPU an excellent solution for the building & construction industry and hand tools.