Product Description

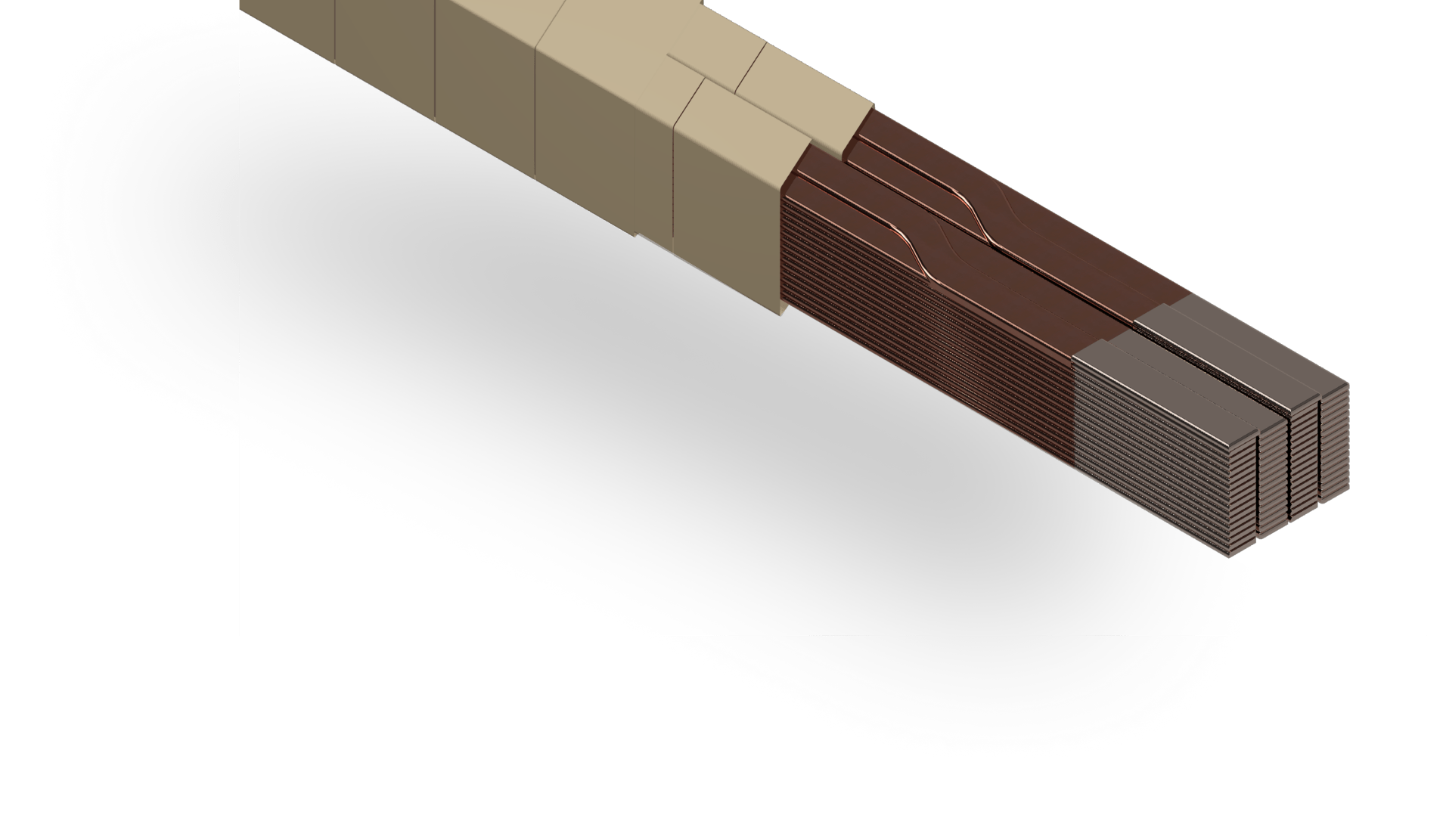

Copper Continuously Transposed Conductors (CTCs) are used as winding materials in power distribution, traction, and furnace transformers. The continuous transposition of copper strands enables balanced electromagnetic performance and effective heat dissipation, making copper CTCs suitable for high-efficiency transformer windings where electrical performance, reliability, and long service life are critical.

Key Advantages

- Reduced eddy current and circulating losses

- Uniform current distribution across strands

- Improved thermal performance and lower hot-spot temperatures

- High mechanical stability during winding

- Enhanced transformer efficiency and service life

Available Variants

- Continuously Transposed Conductor (Standard CTC) Designed for optimal electrical and thermal performance in transformer windings.

- Twin CTC Suitable for higher current ratings and compact winding designs.

- Special Protection Paper-Covered CTC Provides enhanced insulation and protection for demanding operating conditions.

- Netting Tape CTC Offers additional mechanical strength and improved handling during winding.

Applications

- Power distribution transformers

- Traction transformers

- Furnace transformers

- Other heavy electrical equipment requiring high-efficiency windings

Standards & Quality

Manufactured in compliance with relevant IS / IEC standards

Material

High-purity electrolytic copper

APAR’s CTC Design & Manufacturing Expertise

APAR Industries combines advanced manufacturing technology with stringent quality control to deliver high-performance CTC conductors for transformer OEMs and utilities.

APAR also offers a comprehensive range of Transformer Oils, providing reliable solutions across the transformer ecosystem to support efficient and long-lasting performance.